Supply Chain Traceability

Traceability

Supply chain traceability is critical for companies wanting visibility into all levels of their multi-tier supply network to share information with customers, partners, and stakeholders.

Compliance Challenge & Implications

- Failure to meet legal compliance risks negative publicity impacting the brand and inventory being off the shelves.

- Loss of money through blocked inventory due to recalls, lawsuits and penalties.

- United States prohibits imports from China that may have been produced by forced labour under the Uyghur Forced Labour Prevention Act (H.R. 6210) 18th February 2021.

- This includes the Import of all Goods manufactured fully/partially by using forced labour particularly from Xinjiang Uyghur Autonomous region of China.

- The Xinjiang province spans over 1.6 million KM2 and produces 26% of the worlds cotton.

- The Xinjiang province is renown for suppling labour for China’s apparel and footwear factories.

- Xinjiang also exports coal, sugar, grapes, melons, walnuts, tomatoes and polysilicon.

- Polysilicon is used in the manufacture of semiconductors and is the initial building block for manufacturing silicon based Solar PV cells.

Impact

Importers of these products must provide additional documentation so Customs and Border Protection (CBP) will clear shipments bound for USA.

Importers need to:

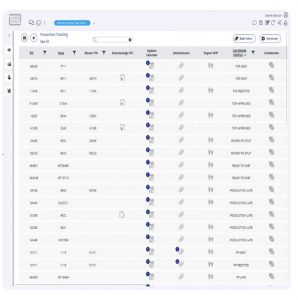

- Trace chain-of-custody across supply chain network.

- Identify risk and verify the origin, supplier and consumption of all materials used in finished products prior to shipment.

- Create comprehensive supplier profiles and evaluations including supply chain hierarchies, geolocation maps and digital threads.

- Leverage transaction data to create compliance certificates to provide proof of admissibility that the merchandise was not produced with forced labour.

Outcomes and Benefits

- Document the chain of custody of cotton from source to importer of record.

- Achieve resilience, compliance, and sustainability.

- Centralize supplier information for all tiers.

- Track material chain-of-custody through immutable blockchain.

- Document every supply chain transaction.

- Create compliance certificate.